PRODUCTION DEPARTMENT

FERPER SPRINGS HAS A CUTTING-EDGE AND EFFICIENT PRODUCTION UNIT USING LAST GENERATION MACHINES IN ORDER TO ENSURE BETTER QUALITY AND PERFORMANCE.

FULL RANGE OF MACHINING

Thanks to the technical expertise of its employees and the large production plant, Ferper Springs provides a full range of mechanical machining processes, such as:

- Welding

- Threading

- Caulking

- Stamping

- Assembling

- Moulding and plastic over-moulding

- Mechanical processing

- Deep drawing

- Blanking

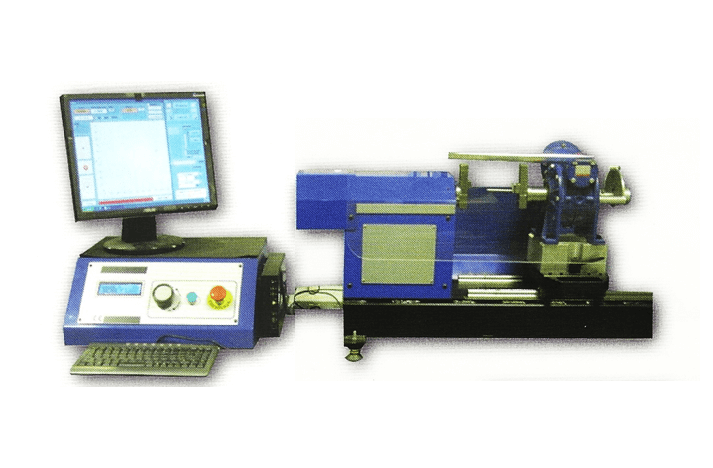

TOOLING DEPARTMENT

In addition to the production department, Ferper Spring owns a machine tool department equipped with various machineries for the construction of equipment, moulds and machines.

The tool room is equipped with:

- Erosion tooling

- Machine Centres

- Milling cutters

- CNC Lathes

- Horizontal and vertical CDL

- Tangential and round grinding machines

- Heat treatment furnaces